I want to share my story from past experiences working at a company in Thailand that was quite unique. Brace yourselves for some workplace adventures!

So, picture this: I found myself working at a company that was incredibly lean. I mean, it was like the company’s motto was “less is more.” But here’s the twist—it lacked a true Kaizen culture. Now, for those of you who are scratching your heads wondering what Kaizen is, let me break it down for you.

Kaizen is a mindset encompassing personal development, workplace organization, process standardization and stabilization, problem-solving, and continuous improvement. It’s like a recipe for success in the business world. And let me tell you, our top manager and owner, despite being soft-spoken, was a real stickler for these things. We’re talking about someone who demanded nothing short of perfection when it came to how our workplace was organized.

Now, you might be wondering how well the company was doing. Well, hold onto your hats because this will blow your mind. While our competitors were barely scraping by on single-digit net profits, this lean machine of a company was generating a whopping 25% net profit! Talk about impressive!

One of our secrets to success was implementing a concept called “one piece flow.” Basically, we aimed to produce goods in flow lines, even though we dealt with low volume but high variety. It was a challenge, especially for our production manager, who initially neglected the basics of scheduling. However, through many cycles of “SDCA” (Standardize, Do, Check, Act), he eventually found the perfect sequencing to keep things flowing smoothly.

As part of the management team, we worked our tails off at the Gemba (that’s a Japanese word for the actual workplace) to develop and improve processes in all areas. From unloading materials with visualized stock replenishment systems to optimizing every single production sub-process, we left no stone unturned. Our goal was to load containers for export of finished goods flawlessly.

And guess what? Day by day, we got better and better. In fact, our labor productivity level reached an impressive 97% of the company’s headquarters in Germany. The remaining 3% could be chalked up to things like ambient conditions and other factors. We were running a tight ship, with only a few quality issues and minimal problems to worry about.

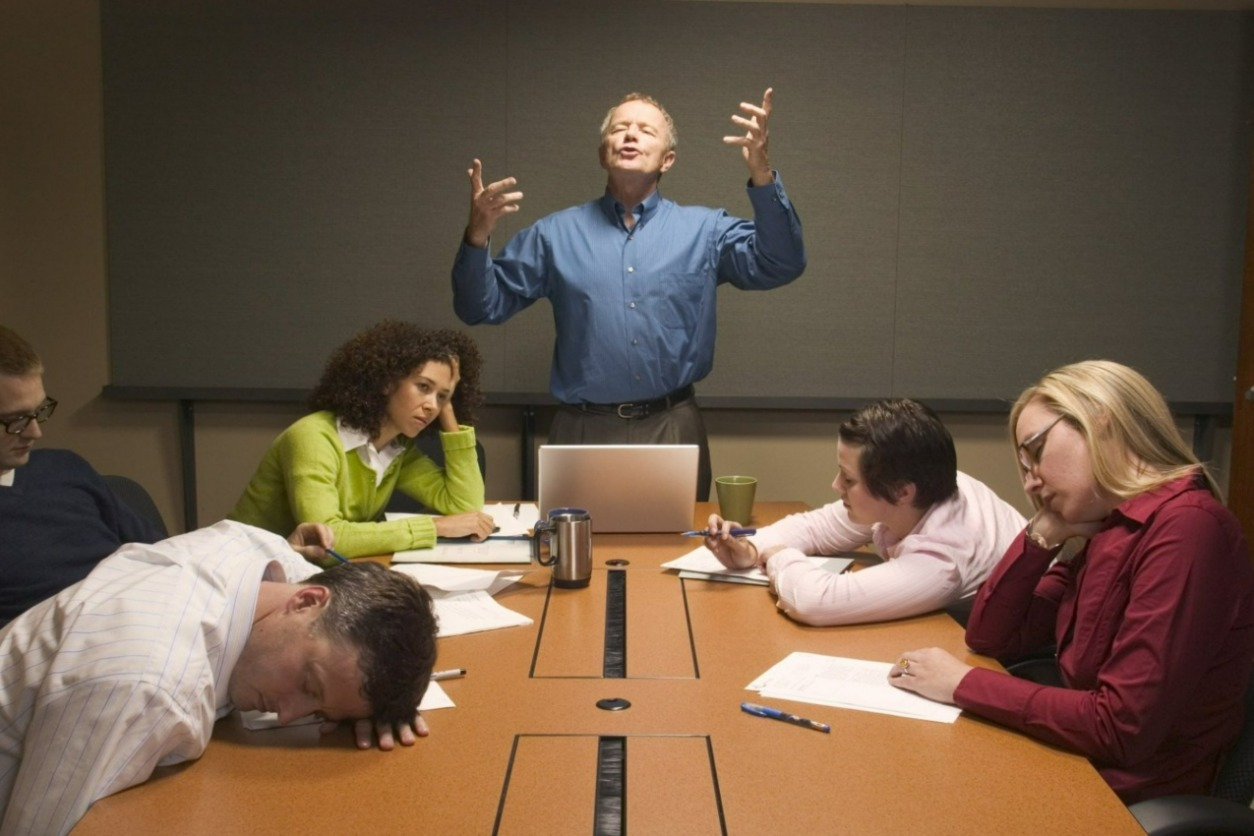

But alas, the universe had other plans. The second law of thermodynamics kicked in, and our pristine workplace organization began to slowly deteriorate. Chaos was creeping in, and I found myself desperately trying various approaches to reinstall motivation and discipline among the team.

One brilliant idea that popped into my head was to create a powerful affirmation that would remind us of the importance of proper workplace organization. We launched a competition, inviting all employees to present their best slogans, with a prize for the winner. We received a ton of fantastic entries, but one slogan stood out—it had the mysterious “5S” in it. I was clueless about what that meant, but everyone else seemed to know it like the back of their hands.

Curiosity got me, and I embarked on a journey to uncover the secret of the “5S.” After some research, I discovered it was all about the five pillars of the visual workplace, as explained by Hirano in his book. These pillars became the foundation of my approach to pursuing 5S, ensuring that workplace organization remained a priority.

And you know what? My journey didn’t end there. Through my exploration of 5S, I stumbled upon the marvelous world of Kaizen. It was like finding a hidden treasure chest full of knowledge and potential. Of course, my journey had its fair share of ups and downs, but it ultimately led me to the insights I’m sharing with my clients today through various MindKaizen programs.

Not too long ago, I had the opportunity to visit a competitor of the company I worked for. They were desperate to escape their net profit black hole and reach the magical realm of 20+% profitability. The absence of 5S was a glaring issue, and it was clear that their lack of self-discipline was holding them back.

Being compassionate, I offered my help, hoping to guide them towards the path of success. But alas, they never responded to my offer or any of my subsequent messages and calls. They were more interested in finding a magical solution, a quick fix, rather than putting in the necessary effort to lay a solid foundation.

Unfortunately, this is a scenario I’ve come across all too often. The failure to implement Kaizen often boils down to a reluctance to embrace the BASICS, the fundamentals that can make a world of difference. It’s like trying to run before learning to walk—a recipe for disaster.

So, my friends, the moral of the story is this: don’t underestimate the power of proper workplace organization and the principles of Kaizen. They might seem simple, but they hold the key to unlocking your company’s true potential.

Remember, success comes to those who are willing to put in the work, embrace the fundamentals, and keep the spirit of continuous improvement alive. It’s not about the magic wand, but rather the dedication and perseverance to do what’s necessary.

I want to learn more.